No products in the cart.

A Simple Terms Blog Post:What is Heat Transfer Printing?

Heat transfer printing — also known as thermal transfer printing — has become one of the most versatile and accessible printing methods for custom gifts, tension fabric backdrops, personalized clothing, and trade show displays. However, many people still have only a vague understanding of this technique. What exactly is heat transfer printing? How does it work? And why has it become so popular in the world of creative customization and portable booth graphics?

This article will explain everything you need to know about heat transfer printing, including its process, advantages, and how it differs from sublimation. Let’s explore how this “magical transfer” brings color and creativity to everything from trade show banner stands to custom tablecloths.

1. Step-by-Step Analysis of the Heat Transfer Printing Process

The logic behind heat transfer printing is simple — “print first, then transfer.” It moves the design from a transfer medium onto the desired surface using heat and pressure. The process typically involves three key steps:

Step 1: Printing the design onto transfer paper

First, use special thermal transfer ink to print your pattern on the transfer paper. Be sure to mirror the image so it appears correctly after transfer. There are several types of transfer paper suitable for fabrics or hard materials — for example, sublimation paper for polyester textiles and vinyl heat transfer paper for items like mugs or metal plates.

This makes it ideal not only for apparel but also for tension fabric backdrops, SEG lightbox graphics, and Pop-up lightbox panels used in trade shows.

Step 2: Positioning and laminating

Next, position the printed transfer paper onto the target surface — whether it’s a T-shirt, trade show tablecloth, or tension fabric display — and secure it with heat-resistant tape. Proper alignment is crucial, especially when printing logos or text for trade show graphics where precision defines professionalism.

Step 3: Applying heat and pressure

Finally, place the item in a heat press (flat press, mug press, or plate press), set the right temperature, and apply pressure for a specific time.

- For fabrics: 180–200°C for about 10–20 seconds.

- For ceramics: 180°C for around 20–30 seconds.

The heat causes the ink to sublimate or melt, allowing it to penetrate and bond with the substrate surface. Once cooled, the pattern is permanently fixed — durable, colorful, and professional-looking.

This fast and efficient process makes heat transfer printing perfect for both small businesses and DIY creators.

2. Why Choose Heat Transfer Printing?

The popularity of heat transfer printing stems from its ability to meet diverse creative needs — from tension fabric backdrop customization to trade show banner stand graphics and custom event tablecloths.

• Ideal for small-batch personalization

Perfect for individuals or businesses producing limited quantities — such as custom uniforms, event giveaways, or personalized hanging banners for exhibitions. Unlike traditional screen printing, there’s no need for costly plate-making, making it cost-effective and flexible.

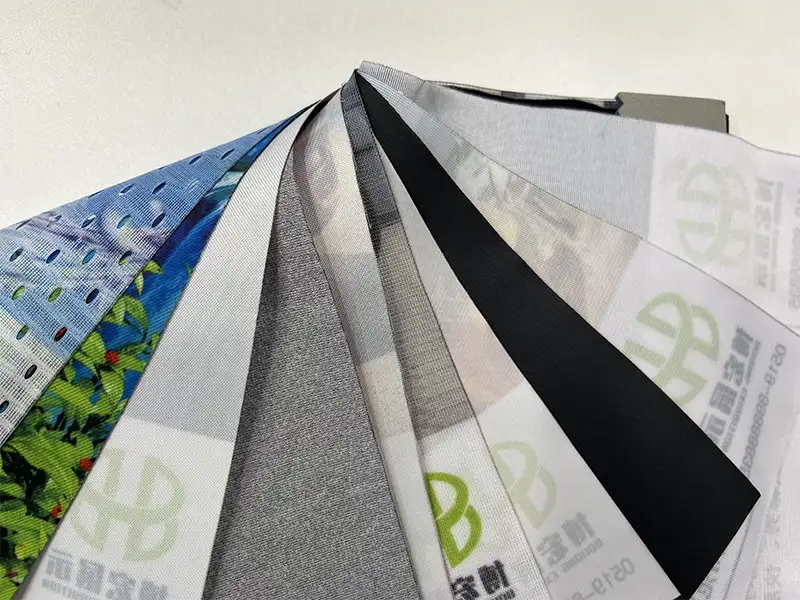

• Works across multiple materials

Whether it’s soft fabric (cotton, polyester, linen) or hard surfaces (ceramic, glass, metal), heat transfer can handle it all. This makes it useful for trade show items like Pop-up lightbox panels, SEG lightboxes, and custom printed tablecloths — delivering consistent branding across your entire booth.

• Excellent color reproduction

Because the process supports high-resolution and full-color printing, it’s great for photos, gradients, and detailed designs — ideal for trade show graphics, branded tension fabric displays, and promotional gifts.

3. Advantages of Heat Transfer Printing

Compared with screen printing or UV printing, thermal transfer stands out for its practicality and cost efficiency.

1. Easy to learn and low entry cost

You only need basic equipment — a printer, computer, heat press, and transfer paper — to start a mini studio. That’s why many small exhibitors use it to produce fabric backdrops or trade show tablecloths on demand.

2. Durable results

Patterns penetrate deeply into materials, offering strong wash and wear resistance — essential for tension fabric booths and reusable display systems.

3. Broad application range

From T-shirts and mugs to portable trade show booths, SEG lightboxes, and hanging banners, thermal transfer fits nearly all creative contexts.

4. Full-color capability

It allows vibrant, photo-quality results with no color registration issues — perfect for exhibitors wanting vivid, seamless trade show backdrops.

4. Heat Transfer vs. Sublimation: Understanding the Difference

While many confuse the two, sublimation is actually a subset of heat transfer printing. Here’s how they differ:

| Comparison | Heat Transfer (Generalized) | Sublimation (A Type of Heat Transfer) |

| Principle | Ink melts or sublimates under heat and transfers onto surface or inside fibers | Ink vaporizes and directly embeds into polyester fibers |

| Materials | Works on fabrics, ceramics, metals, glass, and coated plastics | Best for polyester or coated materials |

| Texture | Slight adhesive feel depending on transfer paper | No adhesive feel, smooth and breathable |

| Color Limit | Prints well on both light and dark materials | Best for light-colored or white materials |

Simply put: for cotton or dark fabrics, or hard surfaces like trade show stands, use general heat transfer; for polyester tension fabric or SEG lightbox graphics, sublimation is the better choice.

Conclusion: Heat Transfer Printing — The “All-Rounder” of Customization

With its easy operation, wide compatibility, and vivid color output, heat transfer printing has become the go-to technology for personalized production. Whether you’re a business customizing trade show displays or an individual creating your own tension fabric backdrops, this printing method provides a reliable, cost-effective, and creative solution.

If you’re ready to bring your ideas to life — from Pop-up lightboxes to custom printed tablecloths — thermal transfer is definitely worth trying.

✨ Start your heat transfer journey today and discover how this simple technique can transform your brand presentation.

We provide one-stop booth design services worldwide and have been rooted in the industry for 18 years.If you need contact us.

WhatsApp:+8615220114725 Quicklyshow Alice

WhatsApp:+8613380363717 QuicklyShow Helen